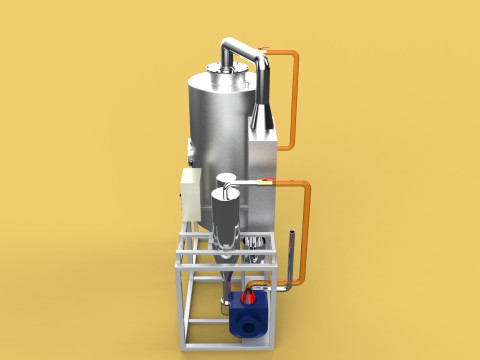

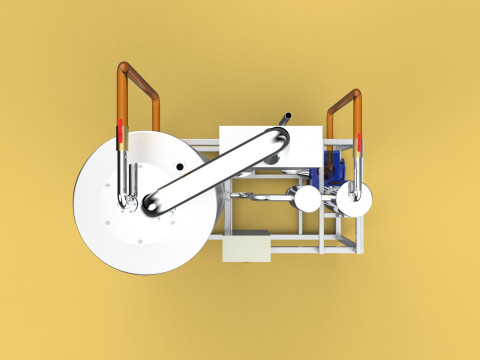

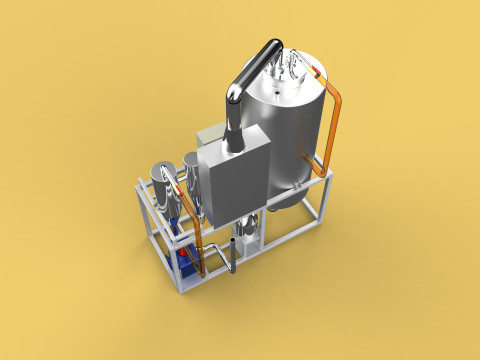

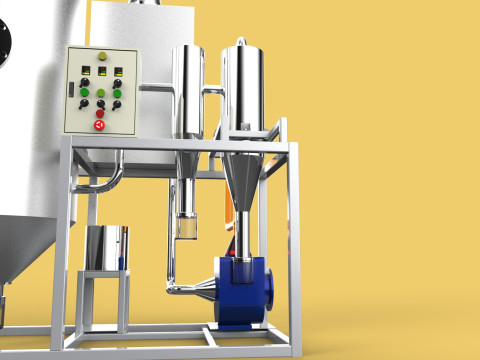

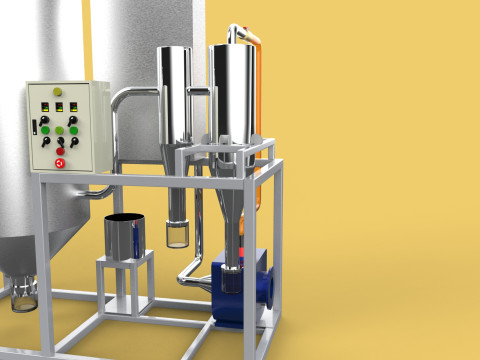

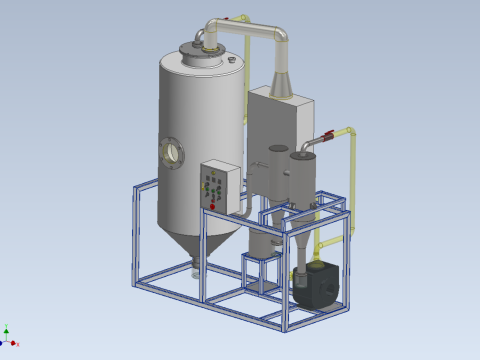

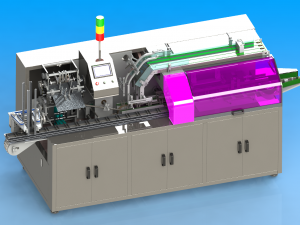

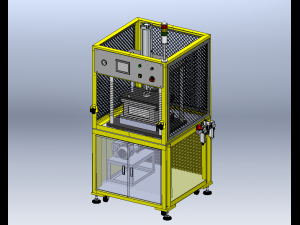

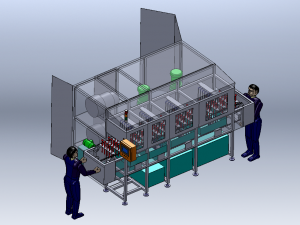

CENTRIFUGAL SPRAY DRYER MACHINE SPRAYING DRYING POWDER GRANULE 3Dモデル

- 利用可能フォーマット: Rhinoceros: 3dm 2.92 MB3DS MAX all ver.: 3ds 612.34 kbBlender: blend 1.70 MBAutoCAD (native): dwg 2.01 MBAutodesk FBX: fbx 2.28 MBIGES: iges 518.84 kb3DS MAX: max 2.67 MBWavefront OBJ: obj 1.20 MBACIS: sat 761.19 kbSketchUp: skp 5.72 MBStereolithography: stl 1.06 MBSTEP: step 343.51 kb

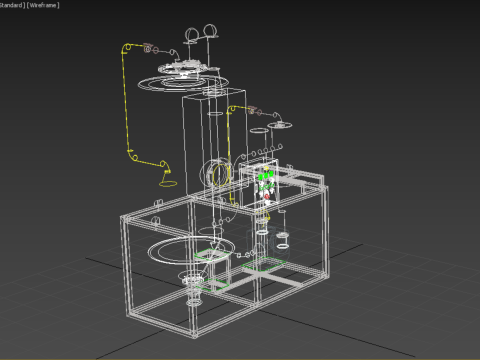

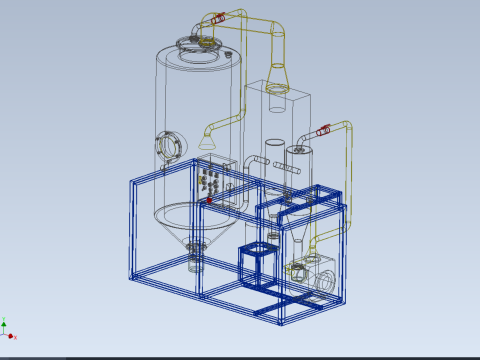

- 多角形:98596

- 頂点:91090

- アニメーション:No

- テクスチャー加工:No

- 装飾:No

- 素材:

- 低ポリ:No

- コレクション:No

- UVW マッピング:No

- 使用中プラグイン:No

- 印刷 準備:No

- 3D スキャン:No

- 成人コンテンツ:No

- PBR:No

- AIトレーニング:No

- ジオメトリ:Poly NURBS

- 展開済 UVs:Unknown

- ビュー:607

- 日付: 2024-12-25

- アイテム ID:547460

- 評価:

The model contains the most popular formats:

1. 3DS MAX: *.max

2. Blender: *.blend

3. Rhinoceros: *.3dm

4. SketchUp: *.skp

5. Wavefront OBJ: *.obj *.mtl (Multi Format)

6. FBX: *.fbx (Multi Format)

7. STEP: *.step *.stp (NURBS)

8. IGES: *.iges *.igs (NURBS)

9. ACIS: *.sat (NURBS)

10. 3DS MAX all ver.: *.3ds (Multi Format)

11. Stereolithography: *.stl

12. AutoCAD: *.dwg

- Each file was checked for opening and full content by the model.

- The 3D model was created on real base. It’s created accurately, in real units of measurement, qualitatively and maximally close to the original.

- Renders Are made in Luxion Keyshot

- “WE PROVIDE 3D MODEL CHEAP PRICE BUT WITH GOOD QUALITY”

- If you need any other formats we are more than happy to make them for you. Contact me for any question :)

Sincerely Your, SURF3D

MORE INFORMATION ABOUT 3D MODELS :

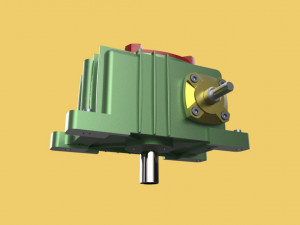

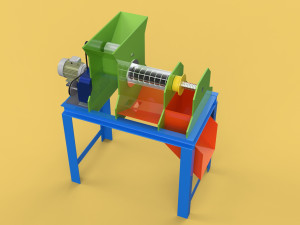

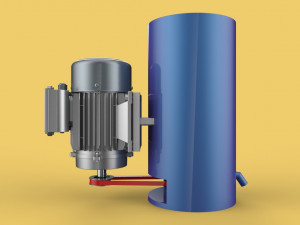

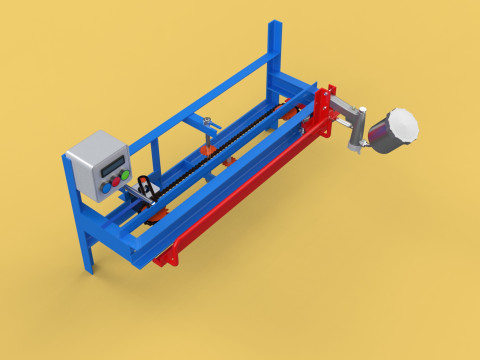

Centrifugal Spray Dryer Machine

A Centrifugal Spray Dryer Machine is a specialized piece of equipment used to produce fine powders or granules from liquid solutions or suspensions. This process involves rapidly atomizing the liquid into a fine mist using centrifugal force, which then comes into contact with a hot drying gas. The rapid evaporation of the solvent results in the formation of dry particles.

Key Features:

Centrifugal Atomization: Utilizes high-speed rotation to create a fine mist of the liquid feed.

Efficient Drying: Ensures rapid and uniform drying of the particles.

Versatility: Suitable for a wide range of materials, including food, pharmaceuticals, chemicals, and more.

Controlled Particle Size: Allows for precise control over the size and distribution of the final product.

High Throughput: Can process large volumes of material efficiently.

Benefits:

High Product Quality: Produces high-quality powders and granules with excellent flowability and solubility.

Improved Product Stability: Reduces the risk of product degradation and spoilage.

Increased Efficiency: Improves production efficiency and reduces processing time.

Versatility: Suitable for a wide range of applications.

Cost-Effectiveness: Can be a cost-effective solution for large-scale production.

Applications:

Food Industry: Drying milk powder, coffee, and other food products.

Pharmaceutical Industry: Drying pharmaceuticals, antibiotics, and other medicinal compounds.

Chemical Industry: Drying pigments, dyes, and other chemical products.

In conclusion, a Centrifugal Spray Dryer Machine is a critical piece of equipment in various industries. Its ability to efficiently and effectively produce high-quality powders and granules makes it an indispensable tool for modern manufacturing processes.

異なるフォーマットが必要な場合、サポートチケットを開き、注文をしてください。3Dモデルをこれらに変換できます: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. 3D シーンは変換しません .step、.iges、.stp、.sldprt などの形式。!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी